Precision plastic solutions

through advanced Thermoforming

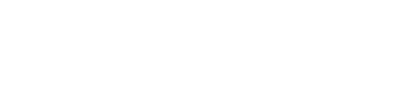

Thermoforming is a highly versatile plastic manufacturing process used to create durable, lightweight components by heating a plastic sheet to a pliable forming temperature and molding it into a specific shape. Once formed, the plastic is cooled, trimmed, and finished to produce a precise, high-quality part that can be used in a wide range of industries. This cost-effective process is ideal for producing both simple and complex parts with intricate details, making it a popular choice for applications that demand reliability, flexibility, and efficiency.

Types of Thermoforming

Vacuum Forming:

A vacuum is used to pull the heated plastic sheet tightly over the mold, creating a precise and detailed part. This method is ideal for producing lightweight parts and is commonly used in industries like automotive, medical devices, and consumer products.

Pressure Forming:

In this process, additional air pressure is applied to force the plastic sheet into the mold, resulting in parts with greater detail, improved surface finish, and more complex geometries. This technique is often used when high precision and fine textures are needed.