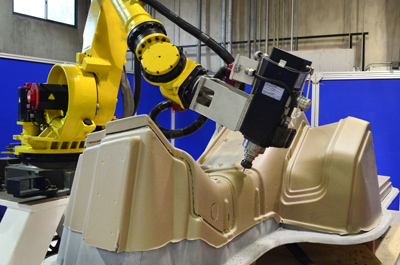

Robotic Trimming.

Our advanced robotic trimming technology ensures that every component we produce meets the highest standards of accuracy and consistency. By automating the trimming process, we achieve precise results, even for intricate and complex designs. This technology not only enhances the quality of our products but also increases production speed, reduces waste, and ensures uniformity across all parts. With robotic trimming, we deliver high-quality, cost-effective solutions that meet your exact specifications.

Precision and Efficiency with Robotic Trimming.

At Medallion Plastics, precision and efficiency are at the forefront of our manufacturing processes, and robotic trimming plays a vital role in achieving these goals. By utilizing advanced robotic trimming technology, we ensure that every component we produce meets the highest standards of accuracy and consistency. This automated process allows us to trim parts with exact precision, even when dealing with intricate designs or complex geometries, making it an essential part of our production workflow.

The use of robotic trimming provides several key advantages over traditional trimming methods. First and foremost, it significantly enhances accuracy. Robots can follow precise paths and maintain tight tolerances, ensuring that each part is trimmed to exact specifications. This consistency results in cleaner edges, better fits, and improved overall product quality. In addition, the high-speed capabilities of robotic trimming increase efficiency, allowing us to process large volumes of parts quickly while maintaining impeccable quality.

Another significant benefit of robotic trimming is its ability to handle complex shapes and detailed parts. Whether we’re working with deep-drawn thermoformed products or components with intricate features, robotic trimming can achieve results that are difficult, if not impossible, to replicate with manual processes. The flexibility of our robotic systems allows us to adapt to a wide variety of part sizes and shapes, providing a reliable solution for even the most challenging designs.

By integrating robotic trimming into our production processes, we also improve overall efficiency and reduce waste. The automation of the trimming process not only speeds up production but also ensures uniformity across every batch, reducing the need for rework and material scrap. This level of precision contributes to shorter lead times and cost savings for our clients, making robotic trimming a key element in delivering high-quality, cost-effective solutions at Medallion Plastics.